•Multiple Language

English, Spanish, Portuguese, Russian, German, Turkish, French, Italian, Czech, Polish, Korean, Chinese, Japanese languages

•Available lens

CR39, Mineral Glass, Polycarbonate, Trivex and Hi-Index lens

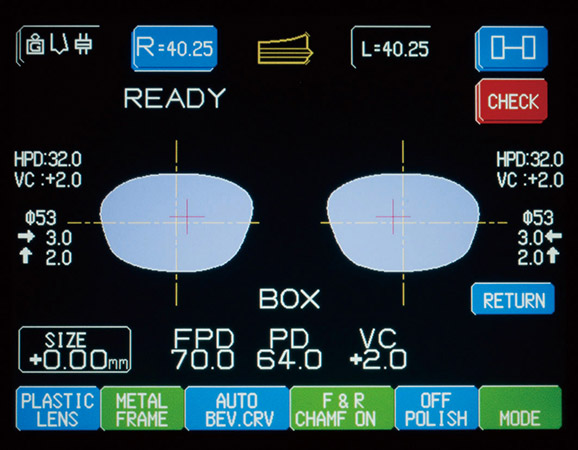

•Touch Panel Screen

High Definition Large Color Screen with Touch-panel Interface. Various Layout Program ‘BOX’ or ‘OPT'(Optical Center) Layout-Style selectable, yet Eyepoint, PD and FPD are also adjustable on the main screen

•Fine Grooving

The optician can check the Grooving-Line/Position in advance, under Step by Step mode. Therefore, the failure of Grooving process is greatly decreased

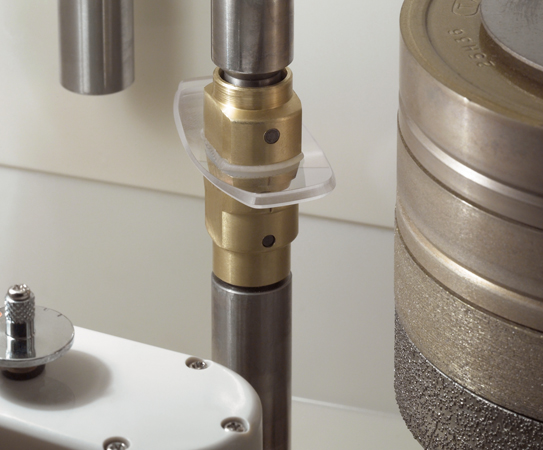

•Slippery Coat Edging Mode (S-Coat Mode)

The machine can cut the slippery lens such as the hydrophobic lens with the optimum stress-free program. This mode is more effective with use of an Anti-slip sheet which lens manufacturer deals in

•High Curved Lens Mode

The operator can easily cut the modern lens with extremely high curve under the 8-curved mode

•Frame Exchange Edging Mode

When re-edging a finished lens for another frame, the used lens can be re-edged after confirming whether it has sufficient dimension for the new frame

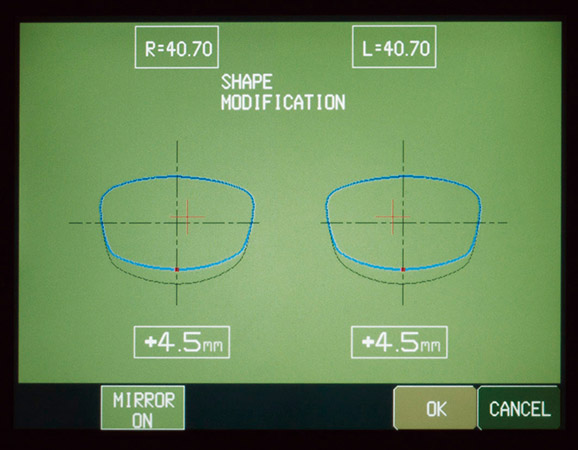

•Shape Modification of Read-in Data

The optician can change the lens size/shape which transferred from FD-80 Scanner

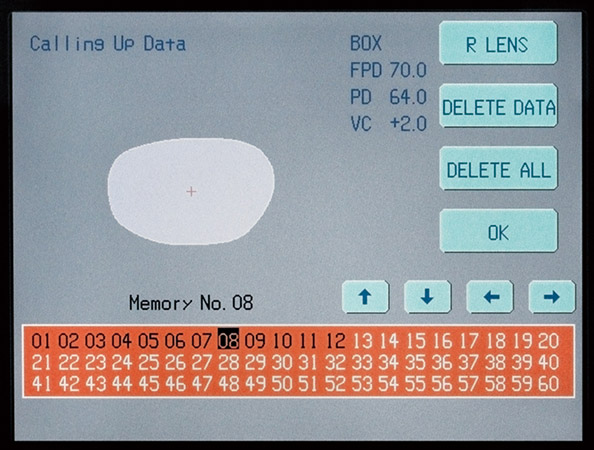

•Built-in 60 jobs Memory

40 jobs rotating tracedata memory + 20 jobs permanent memory

•Re-Edging Mode

Possible to re-edge, even after deblocking the lens cup

•Self Lens-Trace Mode

to convert a sample lens or a pattern plate to a shape-data by a built-in sensor without any external tracer unit

•Easy Update of software program

Possible to update the software program by changing this module

- EDGER

- TRACER

PATTERN MAKER - BLOCKER

- DRILL

- OTHER